Flat roof designs present an aesthetic departure from traditional pitched roofs but the choice must be a safe and practical decision and is best made with a little bit of technical knowledge. Here's a brief overview of the types of flat roofs styles best suited to safely providing coverage over your home and all it contains.

It is important to note that whether you choose a sloped or flat roof, the best roofing system one designed to best practices and constructed by a competent home builder. For your peace of mind, a well built flat roof can outlast three conventional asphalt shingle roofs (commonly installed on most homes) when installed correctly with the right materials. This longevity does come with some added cost as the materials of a well constructed flat roof are of better quality, but when looked at as an investment, you can expect to save on the costs on future maintenance and replacement. Flat roofs are a perfectly practical choice but it still helps to know more about type of flat roof you might choose in building your home.

Generally, when starting to talk about flat roofs we can identify them into two basic types:

- Flat Roofs

- Low-Slope roofs

A true flat roof is just as simple as it states, even and flush but uses sloped systems on top to gently control and direct water to a roof drain or wall scupper that connects to a downspout. In contrast low slope roofs have a much lower slope than traditional roofs and will still lead water off the edge into a gutter and downspout. The pitch of low-slope roofs can vary, but typically they fall between the range of a 2-12 to 3-12 slope. This means for every 2" in height, the length of the roof will be 12" long. The higher the first number (ie the 2) the more steep the angle of the roof. However each of these roof types requires a different method of construction to ensure they will perform correctly.

Flat Roofs

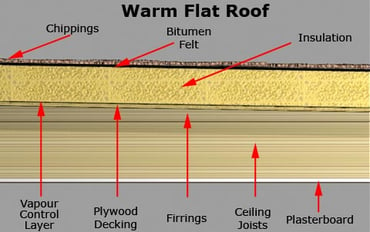

For true or ‘real’ flat roofs the best method recognized by most roofing specialists is the Warm Deck System. This system has all it’s insulation and water proof membranes on top of the exterior deck, and exposes the deck to the warmth inside of the building (hence the name ‘warm deck’). Design features of this roof can vary, but in every typical situation there are 3 basic layers:

- A vapor barrier as your first layer over the top of the roof deck. This is to control the transfer of moisture from inside your home, so that moisture can dry within the home and does not transfer up into the roof insulation where it can cause damage.

- An insulation layer above the vapor barrier, naturally to insulate and retain heat.

- A waterproof protective roof covering above the insulation, which acts as the exterior coat of roof and leads off the surface water.

Material choices for all the three layers can vary depending on the performance characteristics desired, but some of the typical choices for each are listed as follows:

Vapor Barriers:

The most commonly used vapour barriers today are referred to as SBS membranes. SBS stands for Styrene Butadiene Styrene, but it’s easiest to think of them as the same rubbery material your car tires are made out of. It’s flexible and maintains itself in both warm and cold temperatures and are suitable to install in Canadian climates. SBS membranes may be installed in hot asphalt, cold adhesive sheets or heat welded sheets.

Another good vapor barrier is Hot Asphalt Applied Roofing Felts. These are layers of organic felts embedded in hot asphalt and are commonly used on Built-up roofing assemblies used in industrial, tar and gravel systems. The felts typically come on large rolls that are flattened and heat sealed to the roof with a torch.

Other vapor barriers are such as polyethylene sheets and semi adhered or loose laid kraft paper are also used by many builders. While these vapor barriers are typically cheaper, they lack the strength and durability of the other systems and are more easily damaged during construction. This leaves more potential to fail after the rest of the roof assemblies continue and cover up any holes or tears may have been made. For quality flat roof installations, such products should be avoided.

Insulation types

- Polyisocyanurate (generally the highest insulating value, and fire resistant)

- Extruded Polystyrene (Good insulation values and water resistant)

- Expanded Polystyrene (commonly known as Styrofoam, and is the cheapest)

Roof Coverings

SBS membranes again are practical and widely used on roof coverings as they incorporate a synthetic rubber-based technology which gives exceptional flexibility, even in extremely low temperatures. Most residential flat roof systems use SBS as coverings, or cap sheets. The application is typically thicker than when used as a vapor barrier and includes a protective granular layer of stone chips that help avoid the corrosive effects of the sun and weather.

Built-Up Roofing Systems (BUR) consist of layers or plies of roofing felts, with asphalt or bitumen applied between each layer. Built-up roofing is one of the oldest and most durable systems available. Its multiple layers provide extra protection and perform well in extreme weather conditions. While durable, BUR roofs are typically costlier than SBS systems, but can be considered a reasonable investment when you want them to last significantly longer.

The warm deck system is the only flat roofing assembly fully endorsed by both Alberta Infrastructure and the Alberta Roofing Contractors Association and is considered the standard practice for all commercial and institutional building types. The envelope specialists employed in these organizations favor the Warm Deck system because it forms a continuous layer of insulation over the roof structure, that leads to reducing thermal movement and making it more efficient. Also, they have the added advantage of requiring no venting as they are completely above and “outside” the structure of the roof. Both are thermally effective, simple in design and they provide the best cover to any flat roof.

There are other alternatives for flat roof assemblies that are commonly used but generally do not meet the same performance standards as the Warm Deck System, and are not recognized by Alberta Infrastructure or ARCA. Essentially all you need to know is that if you are building a true flat roof, your best bet is the Warm Deck System. We will explain more about some of these alternate roof assemblies when discussing the Low Slope Roofs, as they are more suited to them.

Low Slope Roofs

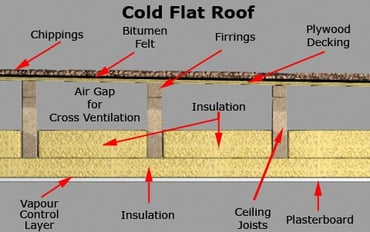

As mentioned, the Low Slope roofs are just flattened conventional sloped roofs and allow similar design aesthetics. Compared to flat roofs, the most important thing to understand is that their vapor barriers sit typically below the roof structure with the insulation placed above within the structural cavity of the attic. The roof deck and shingles lay above this and form the top waterproof surface. With that in mind, sloped roofs will have a large cavity space that has the potential to trap moisture between the vapor barrier below and the waterproof roof above, unless there is proper ventilation, and such roofs are created to have vented attics to dissipate this moisture. With low slope roofs this same need to ventilate the roof cavity exists, except with low slope roofs there is no attic space. To solve this, a cavity needs to be created so that air can cross ventilate over the insulation from one side of the roof to another. One roof system particularly suited to this need is the Cold Deck Roof.

Cold Deck Roofs can be considered the opposite version of a Warm Deck Roof as their name implies. Their top roof deck is ‘cold’ as it is to the outside with the insulation and vapor barrier below within the structural cavity of the roof. The drawing below features a generic example of a Cold Deck system compared to a Warm Deck beside it.

The main difference between two systems is that the cold deck roof combines and seals the entire structural assembly between the ceiling and roof deck while the vapor barrier seals it from the bottom and the roof covering seals it from the top. Because of this, ventilation is required to avoid any moisture that can move and get trapped between the inside and outside of the house. However, with the Warm Deck all the vapor barriers, insulation and roof covering are entirely above and outside the structure. No cavities are created and no venting is required.

With low slope/cold deck systems it is best to allow air to naturally ventilate so that the air is able to move from the low to the high ends of the roof, so that hotter air simply flows up and out of the vented cavity. The specific size and orientation of the roof needs to be accounted for in the design of the venting, with guidance from an appropriate design professional, or roof specialist.

Although more suitable to low slope applications, the cold deck system can be used for flat roofs as well and have been applied on many homes. The main drawback is that the structural joists are not covered from the top with insulation as they are with a Warm Deck System, and a lot more thermal bridging occurs, losing heat to the outside. Another drawback (or consideration) is again that they still require ventilation of the roof cavity and care must be taken to provide a continuous vented space above the insulation. This means that more precaution is necessary and it will still generally under-perform compared to a Warm Deck system. For this reason it is recommend for low slope roofs.

Spray Foam Roof Cavities

Another roof/ceiling type gaining popularity in recent years is the spray foaming of roof cavities. This is done to both true flat roofs, low slope roofs and conventional sloped roofs. Contractors like this system as it is speedy and relatively easy to apply with skilled labor. The spray foam acts like a glue to the structural members of the roof, gaining them strength after its dried to the wood. Despite these advantages, the draw backs are similar to the Cold Deck system, in that thermal bridging still occurs with heat pulled away through the structural members, as it transfers from the warm inside to the cold side of the exterior deck. The foam can be used as the vapor barrier in many cases, but there is the potential that moisture from inside or outside can eventually get trapped between the foam and the wood and eventually cause rot to set in.

While spray foaming is not the best substitute to either a Cold Deck or Warm Deck for an entire roof system, it has proven very useful in some applications. It performs best in insulating concealed areas or areas that are hard to reach with other insulation types, as it is liquid applied and can easily make its way into small openings. Spray foam can also provide an additional layer of insulation to Warm Deck Systems when greater insulating values are desired. Spray foam makes for a useful supplement to our other roof systems, but should not be considered as a replacement for them.

In summary, there's a few key things to consider with a flat roof.

- Use a Warm Deck system for true flat roofs. It is most thermally efficient and has less maintenance issues, as it requires no ventilation.

- Use a Cold Deck system for low-slope roofs. This maintains the same general construction assemblies as traditional roofs and works well if proper ventilation is provided above the insulation.

- Use spray foam sparingly as a modification (but not substitute) to either the Warm or Cold Deck systems.

Was this article helpful?